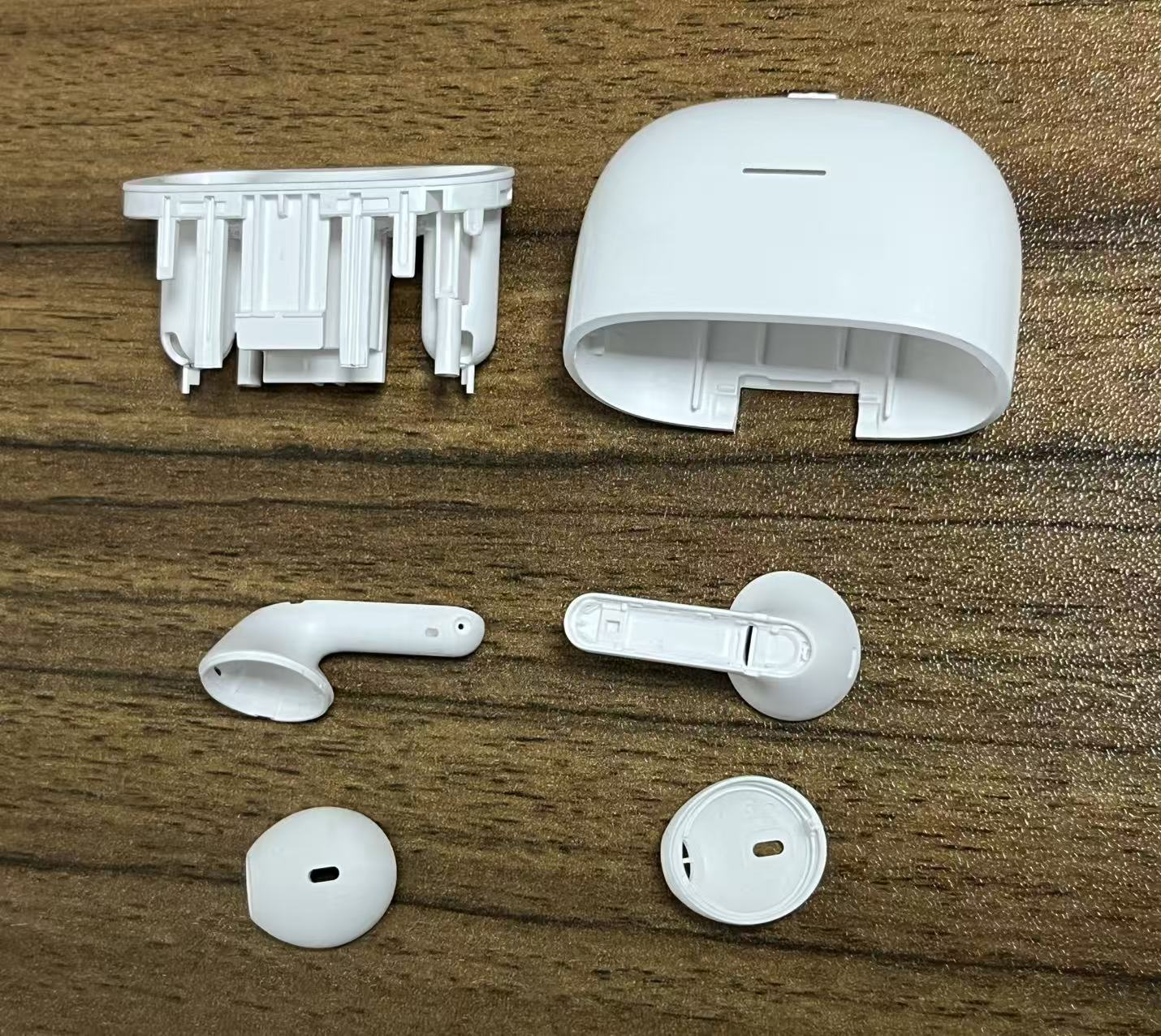

The Role of Custom Molding in New Product Development

Custom injection molding plays a critical role in bringing innovative product ideas to life. From design validation to mass production, this process bridges the gap between concept and market.

From Concept to Reality

Custom molding allows companies to turn 3D designs into functional prototypes and production-ready parts. With advanced mold flow analysis and CNC tooling, we help ensure manufacturability, strength, and visual appeal.

Faster Time to Market

By streamlining development and integrating mold design early in the process, product launches happen faster. Shorter lead times and iterative design help reduce cost and improve outcomes.

Tailored Materials

Each project benefits from optimized material selection—whether the priority is heat resistance, transparency, flexibility, or chemical resistance. Our engineers recommend the best resins for your application.

Collaborative Engineering

We work closely with your R&D or design team, offering DFM (design for manufacturability) support, mold modifications, and trial testing.

From wearable tech to automotive parts, custom molding is the backbone of innovative design. Let LaserShine be your trusted partner in product development.