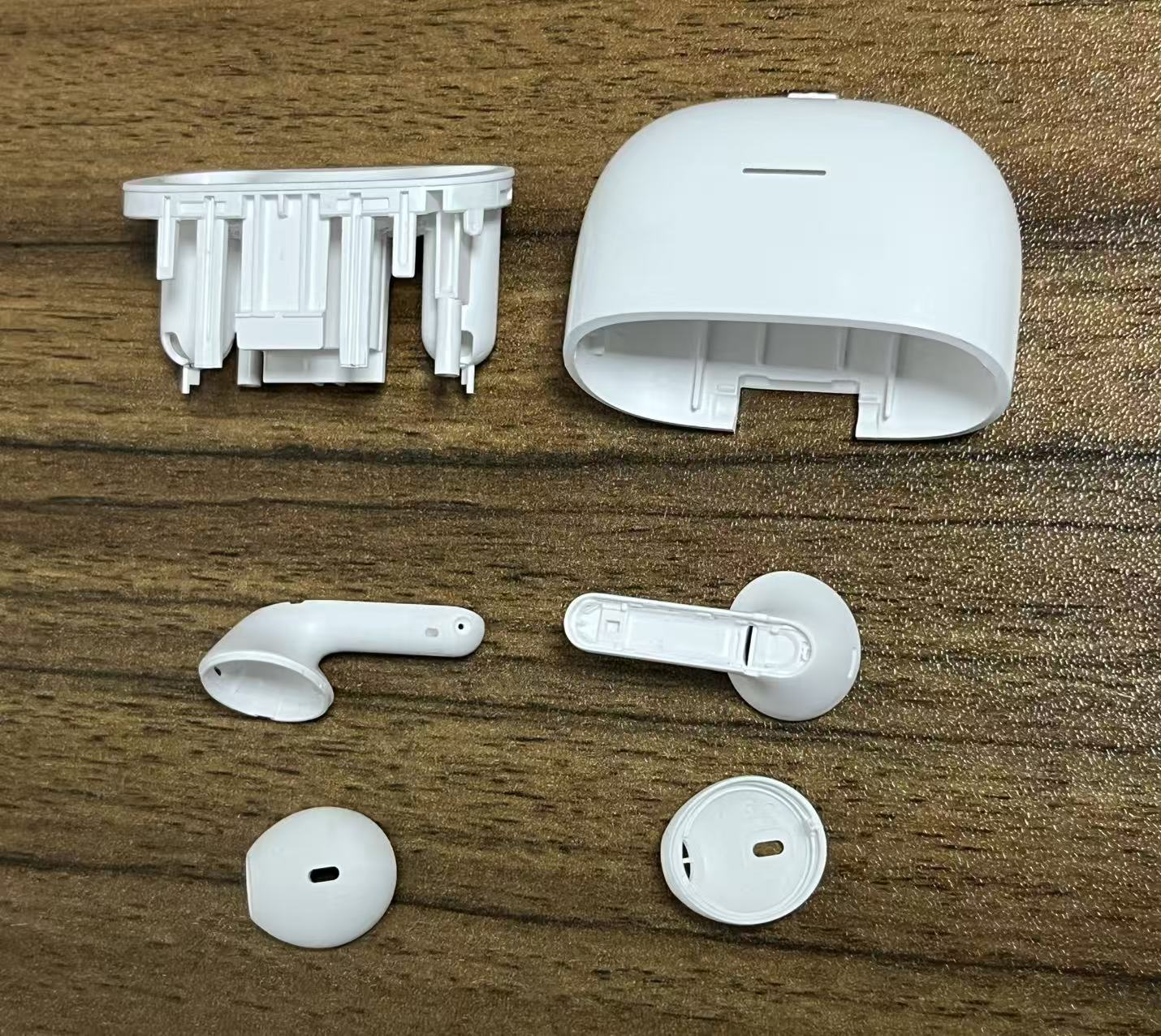

Adding Equipment and Upgrading Injection Workshop for the Second Time

In November 2025, we upgraded the entire injection molding workshop second time and add 11 injection molding machines. The original setup had one inspector per machine, with over 40 injection molding machines and operators sharing the same space. The company rotated all machines 180 degrees and enclosed the area between two rows of machines to create dedicated inspection and packaging zones, achieving human-machine separation and improving the working environment.

After implementation, we confirmed that replacing the old hydraulic machines with Sumitomo servo injection molding machines significantly enhanced production stability, product quality, and efficiency—boosting productivity by at least 15%. Equipping each machine with automated equipment for handling plastic products saved nearly two labor costs per machine, reducing daily expenses by 600-700 RMB per unit. This accounts for approximately 20% of the machine’s production value. Overall, the upgrade and automation increased output by 30%-35% per machine, giving us a competitive edge in the market.

With growing orders, the company has expanded its fleet from 40 to 51 machines. Facing intensifying market competition, we are confident in pursuing upward growth and embracing future challenges.