Applications of Precision Molded Parts in Automotive, Lighting, and Wearable Tech

Precision injection molded parts are essential to modern products in industries like automotive, lighting, and wearable technology. From dashboards to LED lenses and smartwatches, these components ensure performance, durability, and design flexibility.

Automotive Industry

Injection molding is widely used to create automotive parts that require strength, heat resistance, and precision. Common components include instrument panels, clips, sensor housings, and decorative trims. Molded parts must meet tight tolerances to ensure proper fit and function.

LED Lighting

Molded plastic parts such as lenses, diffusers, and housings are crucial for LED lighting. Materials like PMMA and PC offer clarity and durability. A precision mold ensures minimal optical distortion and proper heat management to protect LED performance.

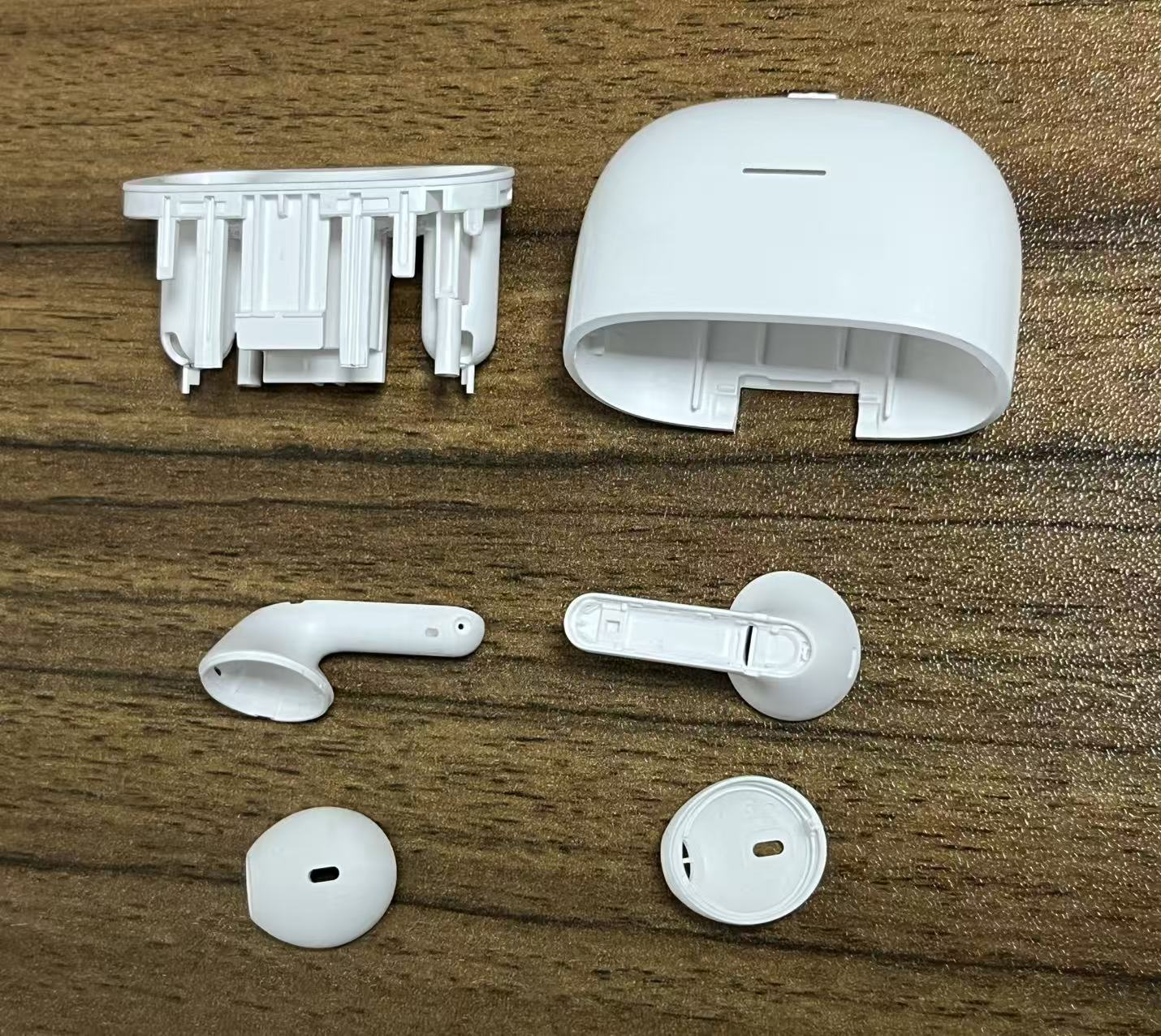

Wearable Technology

Smart devices require compact, ergonomic, and often waterproof enclosures. Injection molding allows production of lightweight parts like earbud shells, watch casings, and silicone bands, often using dual-material (2K) or overmolding techniques.

Why Precision Matters

Across all industries, high-precision molds ensure:

Accurate fit

Reduced defects

Improved product life

At LaserShine, we deliver high-precision molds and injection-molded parts tailored for each application, backed by ISO-certified quality systems and 20+ years of expertise.

Contact us today to explore your next project with confidence.