Adding Equipment and Upgrading Injection Workshop for the Second Time

In November 2025, we upgraded the entire injection molding workshop second time and add 11 injection molding machines. The original setup had one inspector per machine, with over 40 injection molding machines and operators sharing the same space. The company rotated all machines 180 degrees and enclosed the area between two rows of machines to create dedicated inspection and packaging zones, achieving human-machine separation and improving the working environment. After implementation, we confirmed that replacing the old hydraulic machines with Sumitomo servo injection molding machines significantly enhanced production stability, product quality, and efficiency—boosting productivity by at least 15%. Equipping each machine with automated equipment for handling plastic products saved nearly two labor costs per machine, reducing daily expenses by 600-700 RMB per unit. This accounts for approximately 20% of the machine’s production value. Overall, the upgrade and automation increased output by 30%-35% per machine, giving us a competitive edge in the market. With growing orders, the company has expanded its fleet from 40 to 51 machines. Facing intensifying market competition, we are confident in pursuing upward growth and embracing future challenges.

READ More

02

2025.12

Upgrade injection molding shop

In October 2025, we upgraded the injection molding workshop of the company. The upgrading of injection molding workshop has improved the production environment and increase producting efficiency . Rows of machines look neat and orderly. This will bring great convenience to the arrangement of work and production. Do you like? you are welcome to visit and guide our factory. We look forward to your visit. Thank you!

READ More

04

2025.11

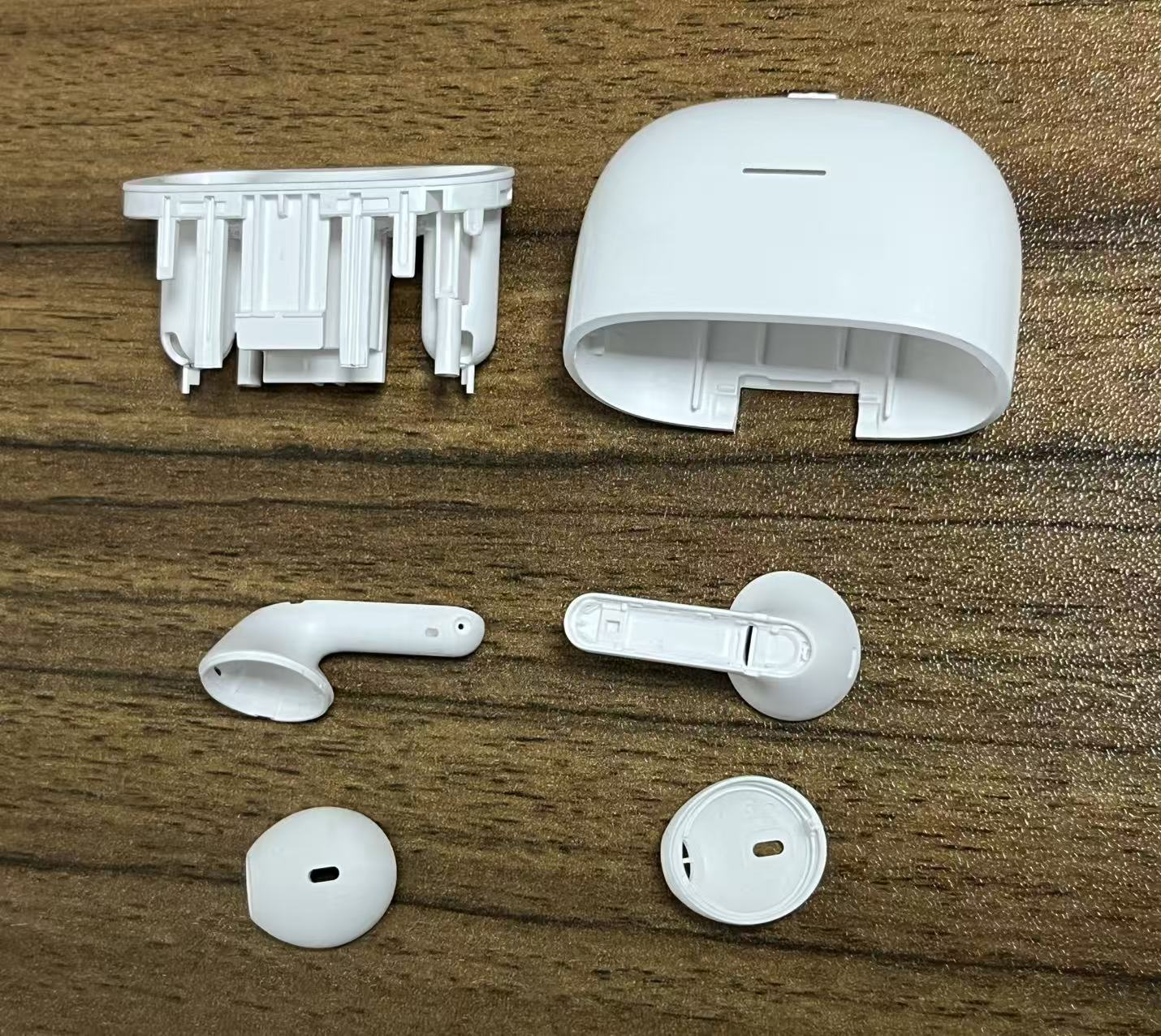

Our Two Keycaps molds and Products

The keycaps made with our two-color mold are compatible with all standard keyboard specifications. All you need to do is remove the corresponding keycaps from your keyboard and replace them with our two-color keycaps—they’re ready to use immediately. Assembly is extremely convenient, and the keycaps produced with the two-color mold will never fade. All our product dimensions strictly adhere to professional standards. Once installed, they offer the same tactile feel as the originals and will not cause any damage to your keyboard. Our products have been sold to numerous countries and regions, including Europe, the United States, Canada, Mexico, Brazil, Australia, Japan, South Korea, and Southeast Asia. Our products are all universal standard items, so you can confidently customize and purchase them without worry.

READ More

31

2025.10

Why Choose a Certified Mold Maker for Your Project

Choosing a mold supplier with industry certifications isn’t just about checking a box—it directly impacts the quality, efficiency, and reliability of your project. Quality Assurance A certified mold maker (ISO 9001, ISO 14001, ISO 45001) ensures traceable quality control systems. Every step—from raw material inspection to final part testing—follows strict standards. Environmental Responsibility Environmental certifications mean the factory follows eco-conscious practices: responsible waste handling, energy efficiency, and safe materials usage. Worker Safety An ISO 45001-certified partner ensures employees operate in a safe and compliant environment, which contributes to operational stability and reduced risk. Long-Term Reliability Certified suppliers are regularly audited and committed to continual improvement. That translates to fewer defects, better communication, and dependable deliveries. At LaserShine, our certifications reflect our dedication to excellence. Work with a partner that puts quality and compliance first.

READ More

28

2025.07

The Role of Custom Molding in New Product Development

Custom injection molding plays a critical role in bringing innovative product ideas to life. From design validation to mass production, this process bridges the gap between concept and market. From Concept to Reality Custom molding allows companies to turn 3D designs into functional prototypes and production-ready parts. With advanced mold flow analysis and CNC tooling, we help ensure manufacturability, strength, and visual appeal. Faster Time to Market By streamlining development and integrating mold design early in the process, product launches happen faster. Shorter lead times and iterative design help reduce cost and improve outcomes. Tailored Materials Each project benefits from optimized material selection—whether the priority is heat resistance, transparency, flexibility, or chemical resistance. Our engineers recommend the best resins for your application. Collaborative Engineering We work closely with your R&D or design team, offering DFM (design for manufacturability) support, mold modifications, and trial testing. From wearable tech to automotive parts, custom molding is the backbone of innovative design. Let LaserShine be your trusted partner in product development.

READ More

28

2025.07