Key Points Analysis Of Mold Manufacturing For Bluetooth Earphones

I. Material Selection and Basic Processes

The mold material must balance strength and durability, prioritizing high-hardness alloy steel or wear-resistant coating steel to withstand high-frequency injection molding production. In basic processes, the melting temperature control directly affects material fluidity, requiring precise adjustment based on plastic characteristics (such as PC, ABS). The mold temperature determines the surface finish of the product; excessive temperature may cause deformation, while insufficient temperature can impair filling effects. Additionally, the parting surface design must ensure smooth mold opening to avoid burrs, and the gate position should optimize the melt flow path to reduce stress concentration.

II. Core Structural Design Details

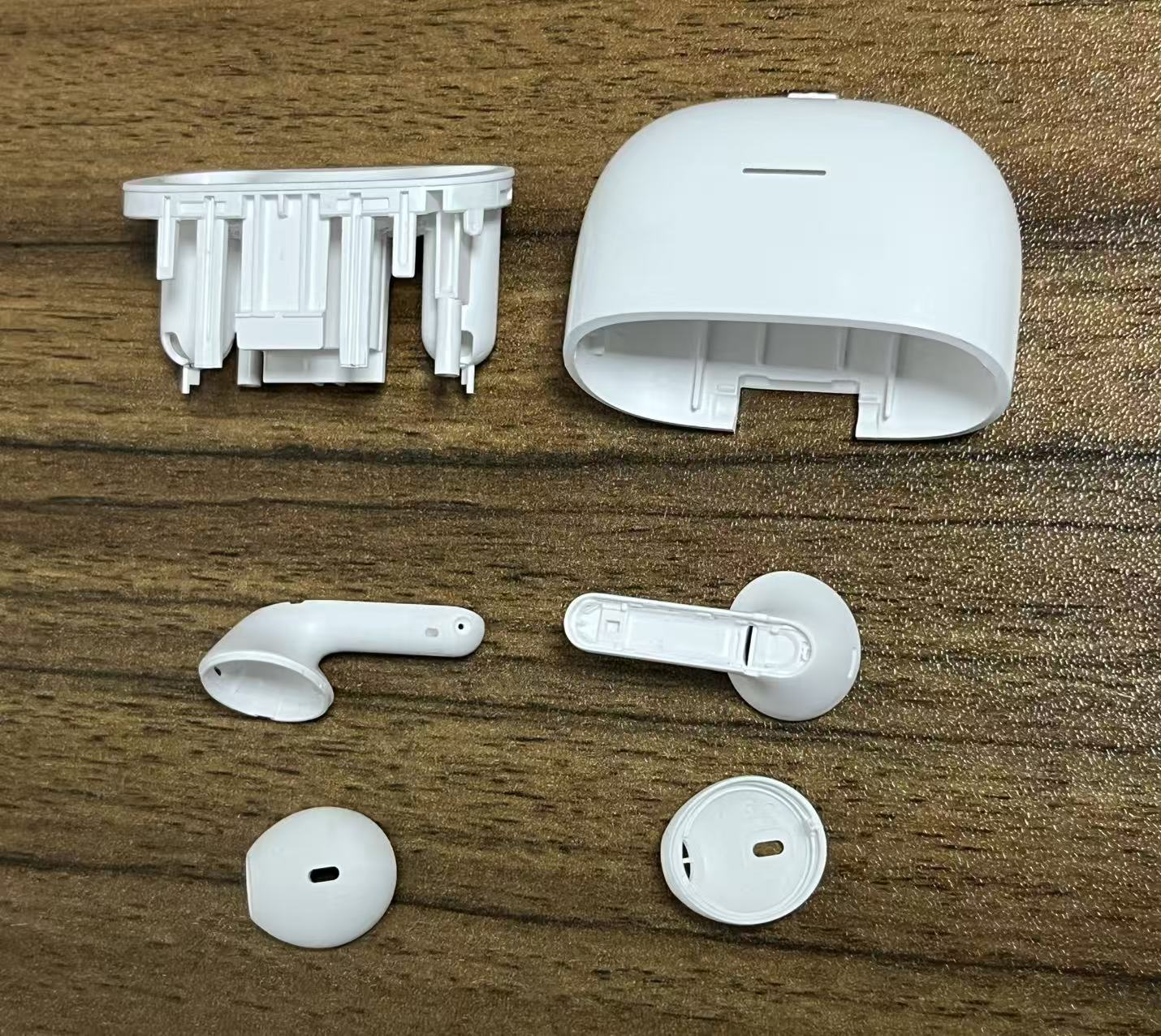

Sliding Blocks and Core Pulling Mechanisms:

Earphone housings often feature undercut structures, necessitating angled ejector pins or sliding blocks for demolding. For instance, the undercut at the earphone stem can be efficiently addressed with spring steel ejectors to prevent interference. Complex curved surfaces require sliding block inserts with T-slot guides to ensure alignment between the core pulling angle and the undercut. The strength of sliding blocks must be verified through finite element analysis to prevent deformation after prolonged use.

Cooling System Optimization:

Uniform cooling is crucial for product dimensional stability. Molds should incorporate annular or conformal cooling channels to allow coolant to quickly cover high-temperature areas, thereby reducing cycle times. For example, thick-walled sections of the charging case require enhanced cooling to prevent warping caused by internal stress.

Ventilation and Ejection Design:

Vent slots must be positioned away from visible surfaces, typically along the parting line or insert gaps, to avoid gas entrapment and porosity. Ejection mechanisms should use balanced ejector pins to ensure even force distribution, preventing ejection marks or deformation.

III. Adaptation to Smart Wearable Features

Lightweighting and Fit:

Molds must support thin-wall injection molding, with wall thicknesses between 0.8-1.2mm, while optimizing melt flow through Moldflow software simulation to maintain strength. For example, the curved surfaces of the ear tips should conform to ergonomic principles to reduce wearing pressure.

Multi-functional Integration:

For noise-canceling microphones, sensors, and other modules, molds must provide precise locating holes with tolerances within ±0.005mm. Additionally, assembly gaps for components (such as magnetic charging contacts) should be adjusted through trial molding to ensure functional reliability.

IV. Quality Control and Maintenance

Trial Molding and Parameter Optimization:

Initial trial molding must validate defects such as filling rate and shrinkage, optimizing the product by adjusting parameters like holding pressure time and injection speed. For example, high-gloss surfaces require extended holding pressure to eliminate flow marks.

Periodic Maintenance:

Regularly inspect sliding block wear, cooling channel blockages, and other issues, and use nitriding treatment to enhance surface hardness. Mold lifespan management should record production counts and predict replacement cycles for critical components.

V. Innovation Trends and Challenges

As TWS earphones evolve into bean-shaped and sports-ear-hook designs, mold design must break traditional boundaries. For example, open-ear earphones without ear tips require molds with enhanced ventilation. The integration of AI functions (such as translation modules) necessitates miniaturized cavity designs. In the future, 3D printing technology may facilitate rapid prototyping of complex inserts, further shortening development cycles.